MQL technology applications

Our LUBRIX MQL systems rise to every challenge.

Applications

Every LUBRIX MQL system offers a standard set of features that have been especially designed to cope with the challenges of using MQL technology in all kinds of machine tools and machining processes. Different machine designs tax the features offered by an MQL system in different ways; all these demands are met to the full by LUBRIX MQL systems.

On many an occasion, these types of machine tool are ideal when short tooling times require a correspondingly short response time before the MQL medium is supplied to ensure the ideal lubrication process. The control algorithms housed in LUBRIX MQL systems allow individual volume flows to be fed to the tool at high speed and with extremely fast response times. The required lubricant volume is discharged onto the tool’s blade within a fraction of a second of the start-up signal triggering.

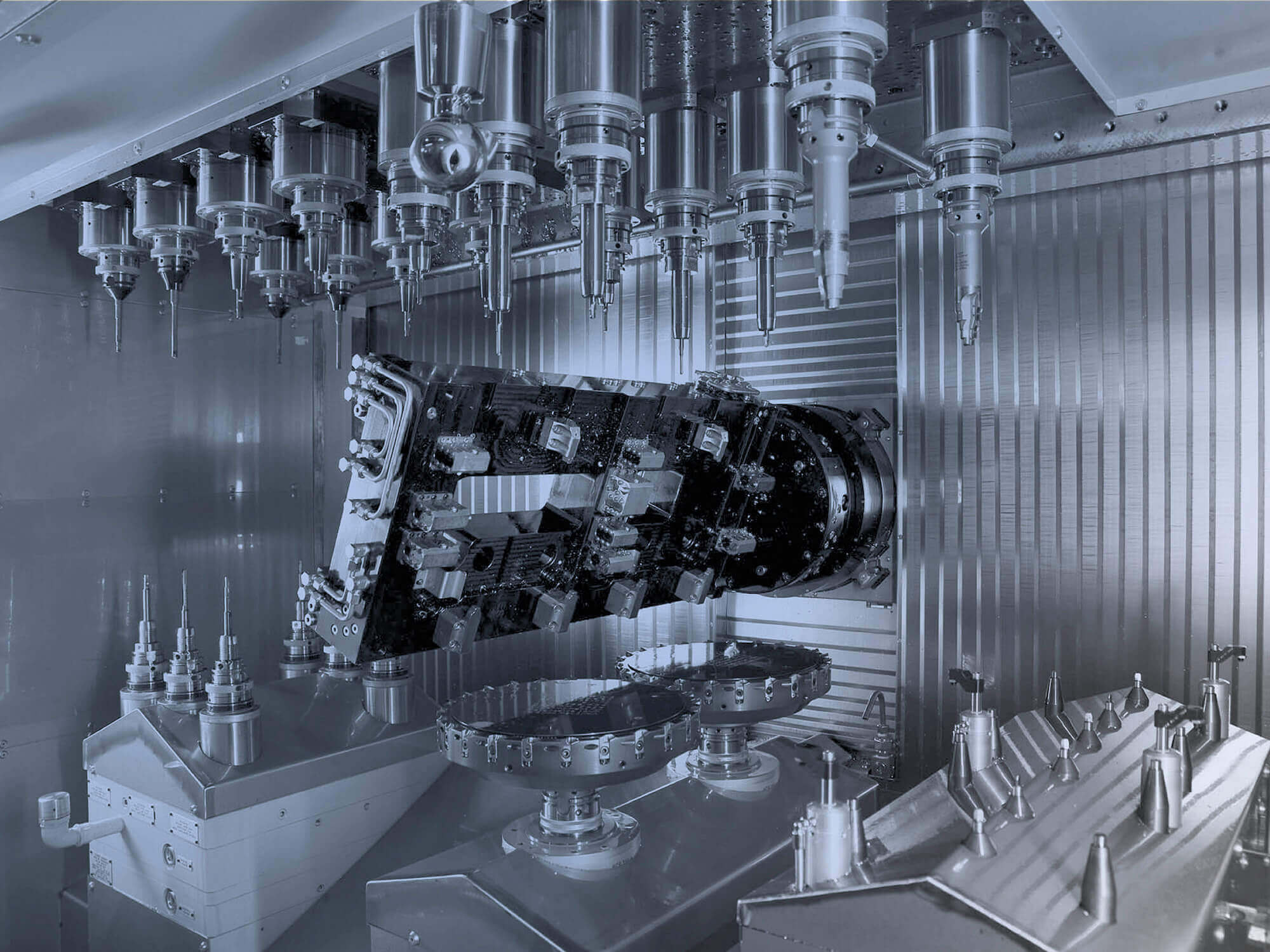

On machine tools with multiple spindles working simultaneously, it is not just the response time that plays a major role but also the fact that the lubricant is distributed evenly across the simultaneously running individual tools. In LUBRIX MQL systems, the generation of aerosol is dynamically regulated in a very specific way. This results in a simultaneous, lossless and controlled supply of MQL volume flows to the individual tools. The MQL medium is distributed completely evenly across a number of simultaneously running spindles.

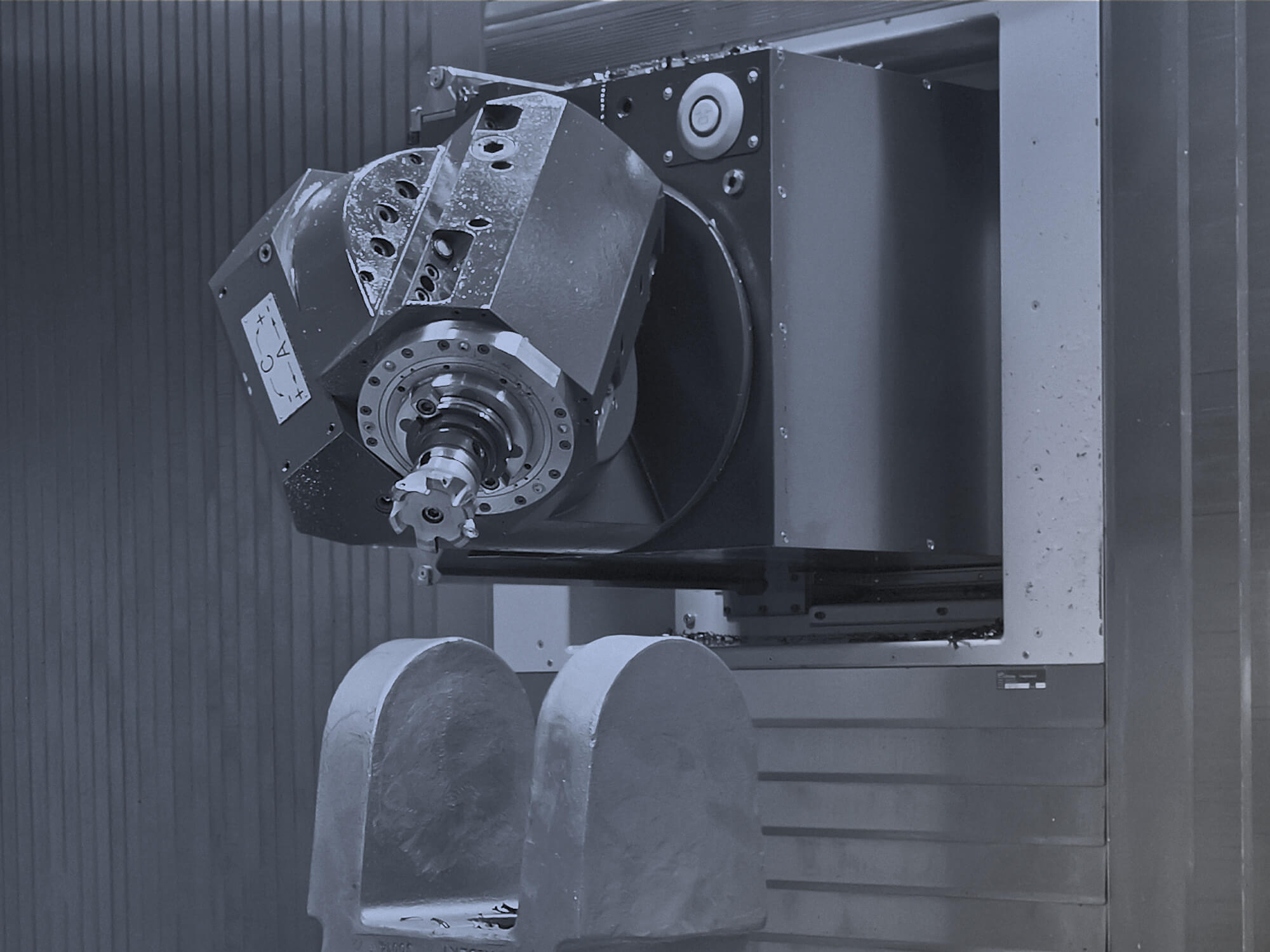

Due to design constraints, the channel lines supplying the MQL medium to larger drilling and milling centres equipped with standard or swivel-head spindles often offer poor flow performance. Whether in the machine’s feed lines or the channels in the spindle assembly, a number of obstacles, such as constricted or diverted MQL volume flows, need to be overcome. The specific features offered by LUBRIX MQL systems allow the MQL medium to be transported reliably within the feeding system to the cutting edge of the tool’s blade even if such obstacles are present.

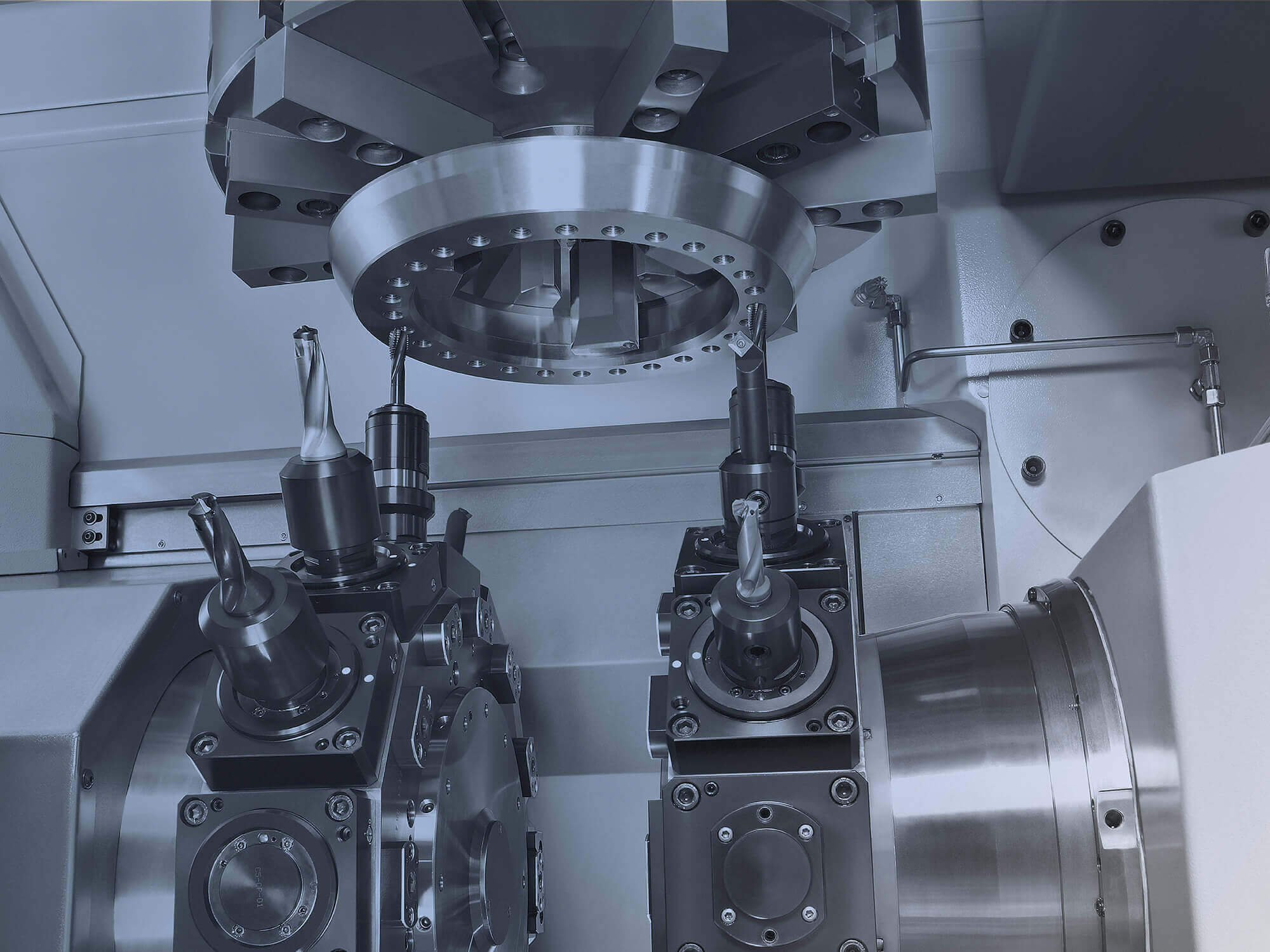

In modern single or multi turret lathe centres, the configuration may involve one or more turrets, or also additional spindles, in the same machine room. All of these points of consumption run simultaneously and typically require individually adapted quantities of the MQL medium as lubrication. LUBRIX MQL systems fully meet the challenges posed by such machinery as – depending on their design – the systems are capable of delivering varying MQL volume flows to different tools at the same time. This reliable process works on stationary and powered tools.

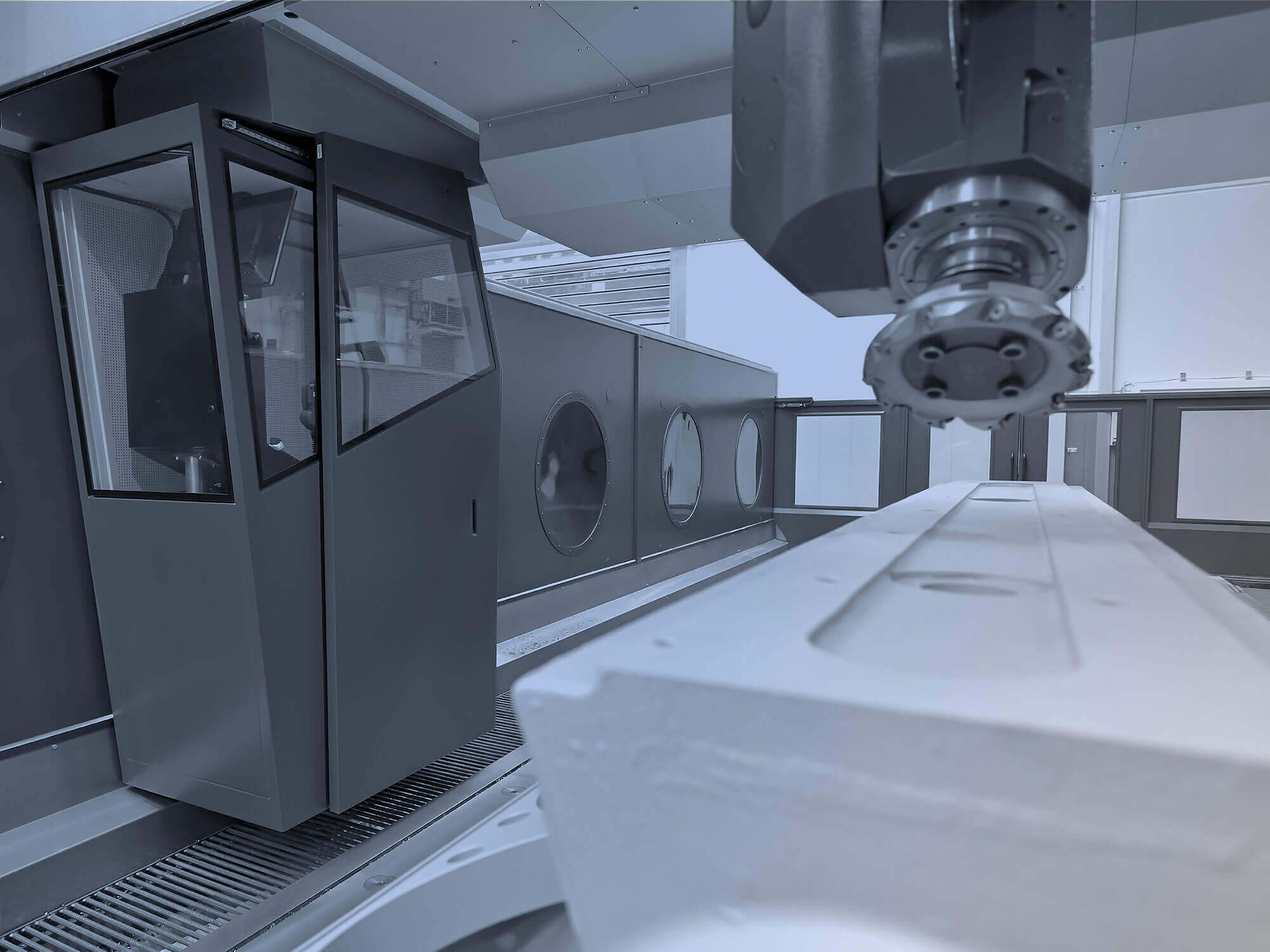

A long line run often poses major challenges where portal milling machines are concerned. The MQL system’s feed channel often runs more than 30 m before reaching the tool’s spindle, which also physically impacts the volume flow of the MQL supply. Even when faced with such constraints, LUBRIX MQL systems continue to regulate the MQL flow in an optimum, stable process. Long-routed lines therefore pose no difficulty for our company’s technology.