Minimum Quantity

Lubrication Technology (MQL)

When using Minimal Quantity Lubrication (MQL), the lubricant is delivered directly to the cutting edge of the tool as an oil mist (aerosol). The LUBRIX MQL system was specifically developed for maximum performance in through tool applications. The LUBRIX systems offer the highest efficiency and consistency of lubrication delivery in the industry.

Twenty years of experience and thousands of installations makes LUBRIX uniquely qualified to address all of your MQL needs.

LUBRIX – the MQL specialists

We specialize entirely in the development, production and sale of MQL technology and system components.

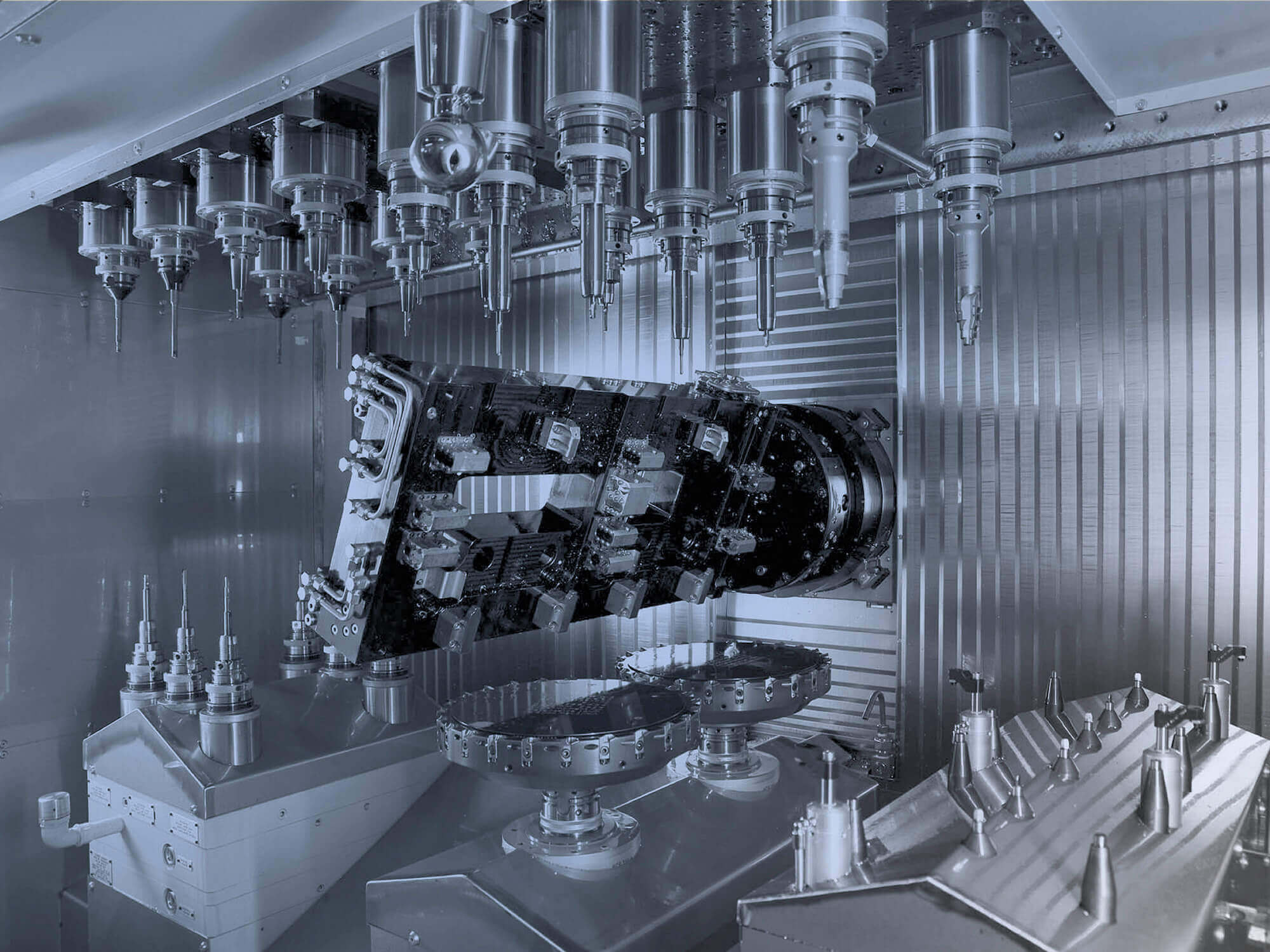

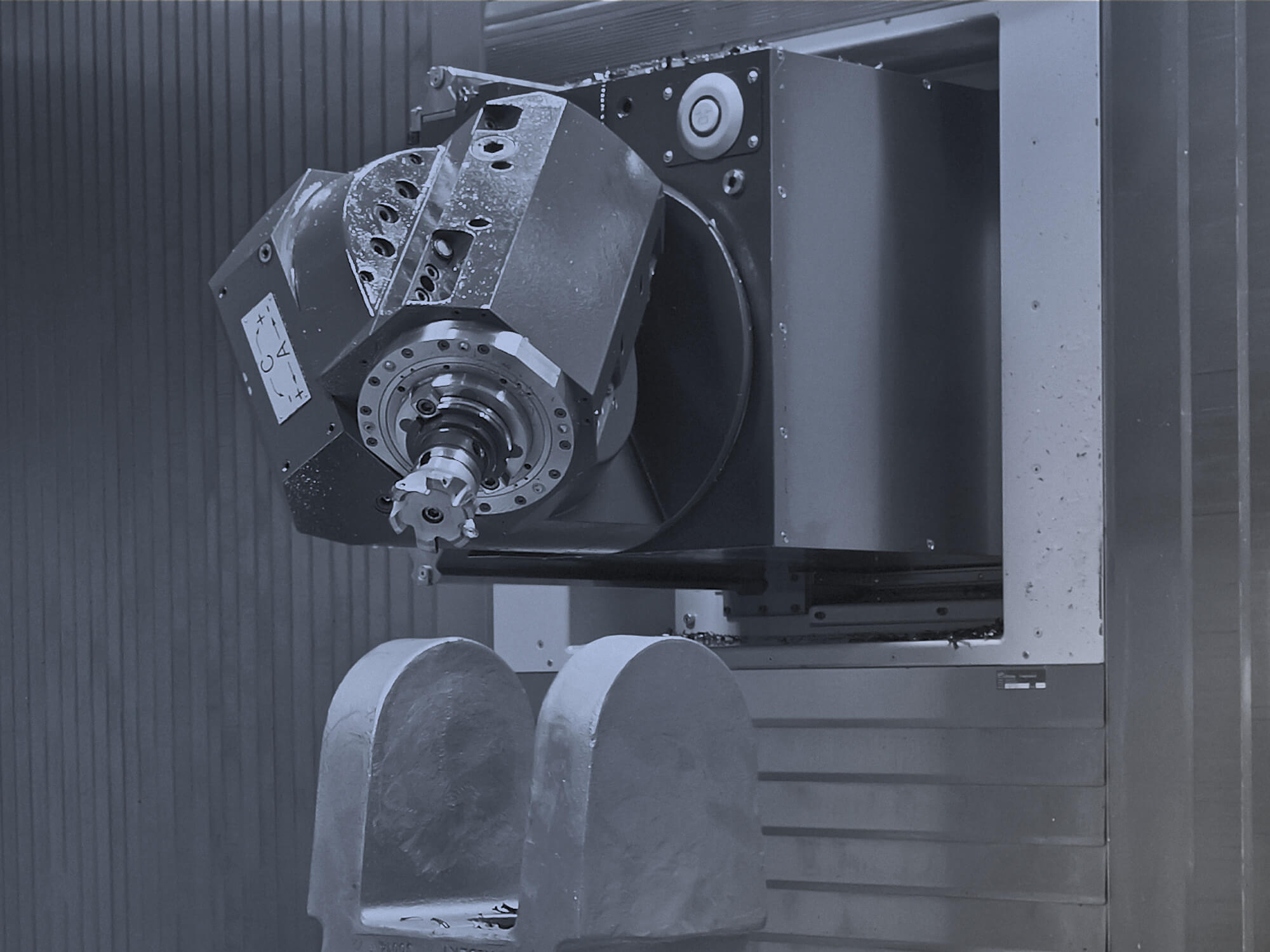

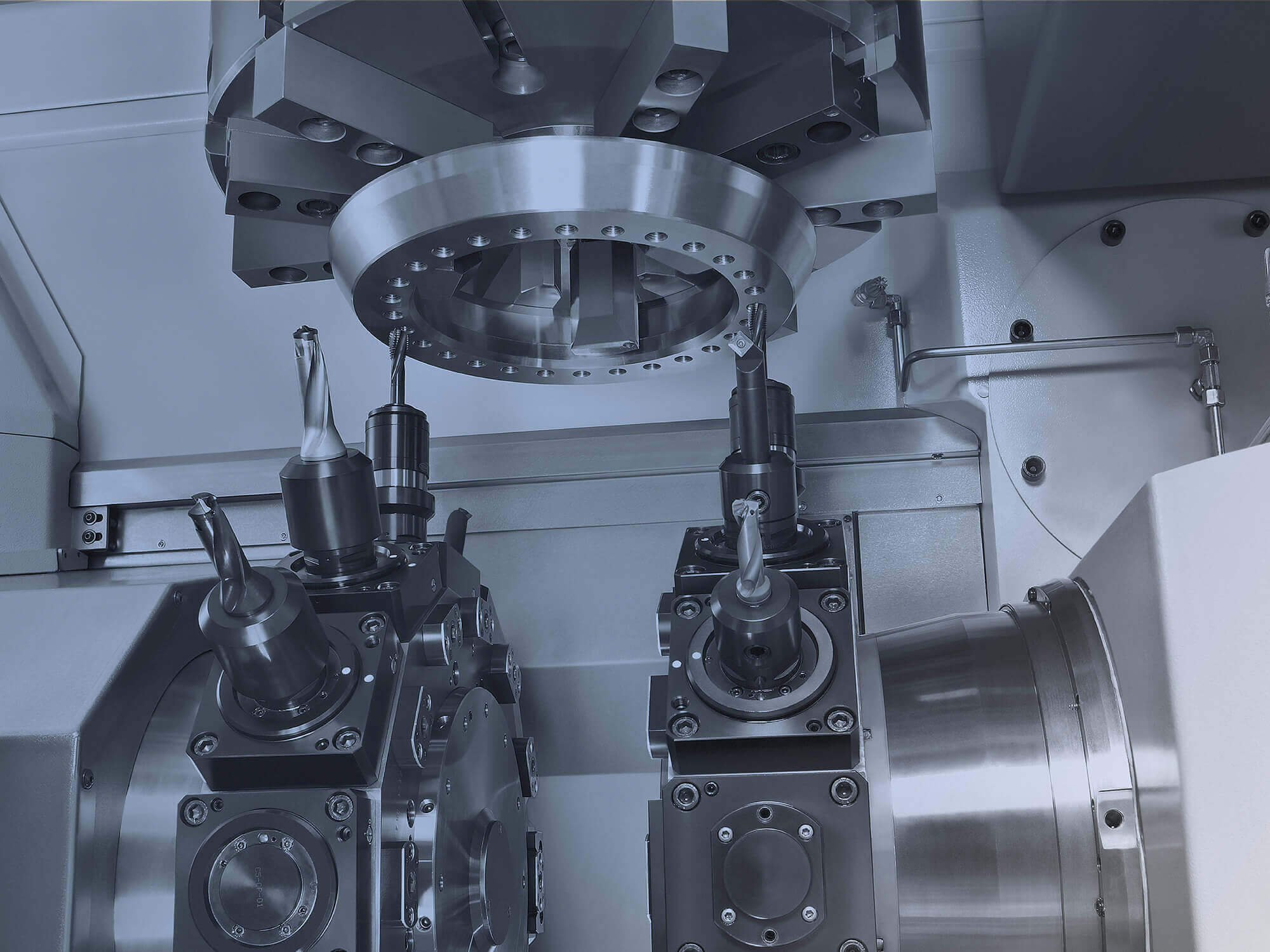

Every LUBRIX MQL system is well suited for integration with modern machine tools. MQL is most effective when fed internally through spindles, turrets and tool systems.

Integrated dynamic aerosol generation along with modern process monitoring within our MQL systems enable the highest levels of process consistency and reliability. The functionality and dynamics of LUBRIX products offer exceptional performance, especially in demanding situations such as:

Success through innovation

Every year, several hundred machine tools across the globe are equipped with LUBRIX MQL systems. Exceptional product performance of our current products is a result of our many years of experience and strong innovation skills in the field of MQL technology.

Our users recognize numerous benefits from our years of experience and innovation in the field of MQL technology.

Applications

Our products

LUBRIX MQL systems are equipped to handle a variety of processes or machine tools.

Every LUBRIX MQL system offers a standard set of features that have been especially designed to cope with the challenges of using MQL technology in all kinds of machine tools and machining processes. For particularly demanding applications, optional extras can also be incorporated into the systems. LUBRIX offers two MQL system series. The LUBRIX V Series MQL systems are designed with the flexibility and capability for any applications that end users demand, and cover every conceivable monitoring feature desired. For less challenging applications, the LUBRIX S Series is a more cost-effective solution while still offering exceptional performance and a large number of the process-monitoring functions.

V Series MQL systems at a glance

S Series MQL systems at a glance

LUBRIX series models compared (PDF)

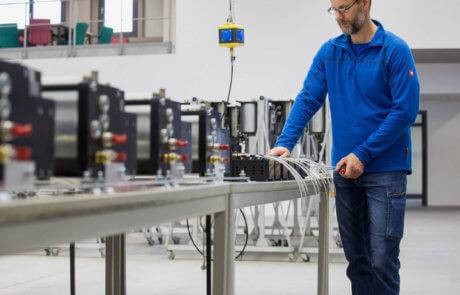

LUBRIX – the company

LUBRIX GmbH was founded in 2001 and since then has dealt exclusively in MQL technology. The company has already acquired numerous awards, including from the state of Baden-Württemberg, for its innovations.

Since the company was founded, thousands of machine tools have been equipped with LUBRIX MQL systems. Experiences gained from these process installations continuously flow into the company’s product development activities. The summer of 2018 also saw the LUBRIX GmbH move into a new production facility where increased space and modern production plants offer the company the capacity to grow further.